Tailored to production needs

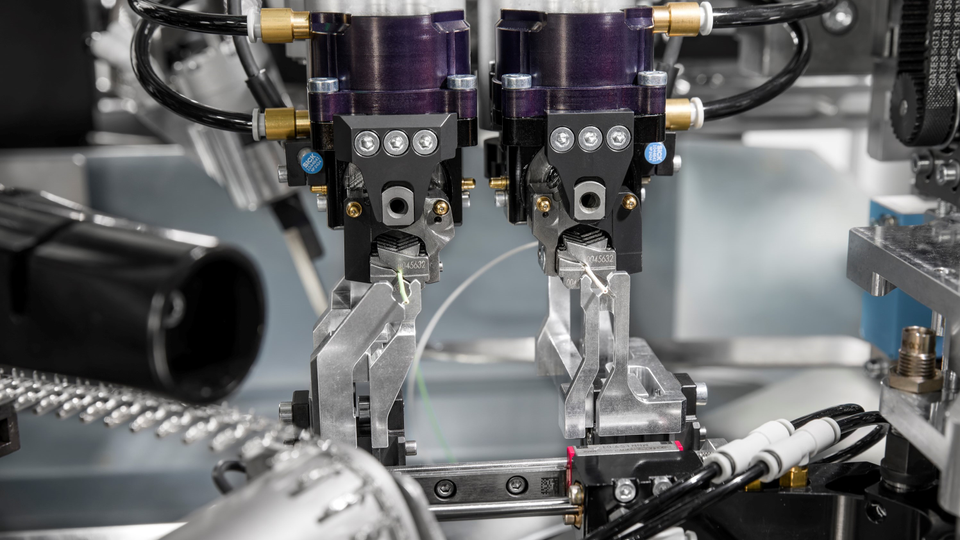

With a 2+2 station configuration and all essential quality control tools, the Sigma 586 is ideally suited for high-volume production.

The Sigma 586 enables fully automated, high-performance production and output of twisted cables, including crimping, sealing, and intelligent wire shifting for any open end configuration.

With a 2+2 station configuration and all essential quality control tools, the Sigma 586 is ideally suited for high-volume production.

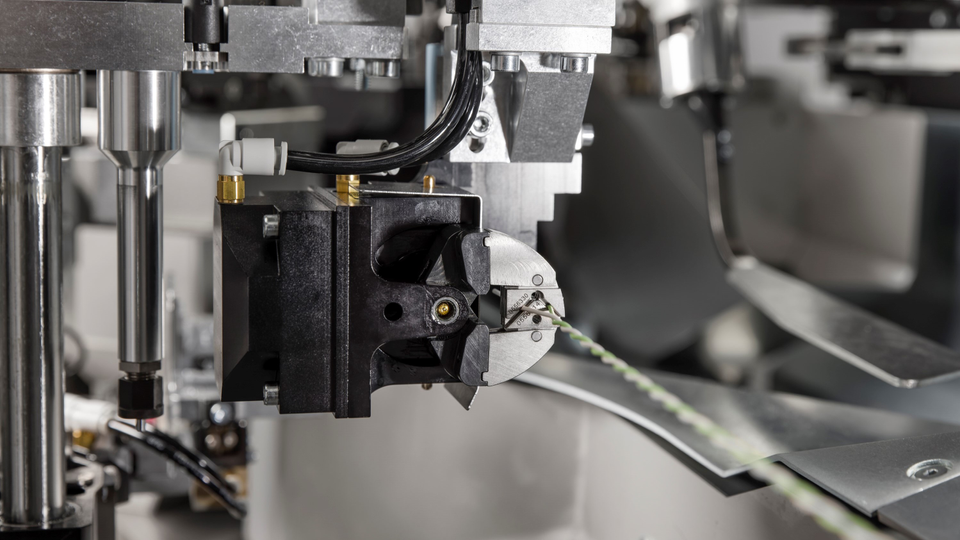

The variable open end (VoE) processing set offers intelligent and integrated wire position adjustment for a wide range of open end configurations.

Automation minimizes operator influence and reduces human errors, while Q1250 algorithms control the production and ensure high quality results.

The on-site changeable processing set of the Sigma 586 allows for both large wire gauges and smaller open end configurations.

| Specification name | Specification value |

|---|---|

| Wire length, processing on both sides min. | 700 mm |

| Wire length max. | 7000 mm |

| Strip length side 1 min. (processing set VoE 8-8, VoE 8-15) | 0.1 mm |

| Strip length side 1 max. (processing set VoE 8-8, VoE 8-15) | 18 mm |

| Strip length side 2 min. (processing set VoE 8-8, VoE 8-15) | 0.1 mm |

| Strip length side 2 max. (processing set VoE 8-8, VoE 8-15) | 28 mm |