Heat Shrinking

Heat ShrinkingIRMO 110V

The IRMO is an infrared shrinking appliance for products with diameters up to 16 mm (0.6 in). It's ideal for mobile use thanks to its small size and integrated trigger button.

Heat ShrinkingIRMO 230V

The IRMO is an infrared shrinking appliance for products with diameters up to 16 mm (0.6 in). It's ideal for mobile use thanks to its small size and integrated trigger button.

Heat ShrinkingIRDT 110V

The infrared shrinking appliance IRDT is ideal for stationary use due to its small size and stable base, making it perfect for processing product diameters up to 16 mm (0.6 in).

Heat ShrinkingIRDT 230V

The infrared shrinking appliance IRDT is ideal for stationary use due to its small size and stable base, making it perfect for processing product diameters up to 16 mm (0.6 in).

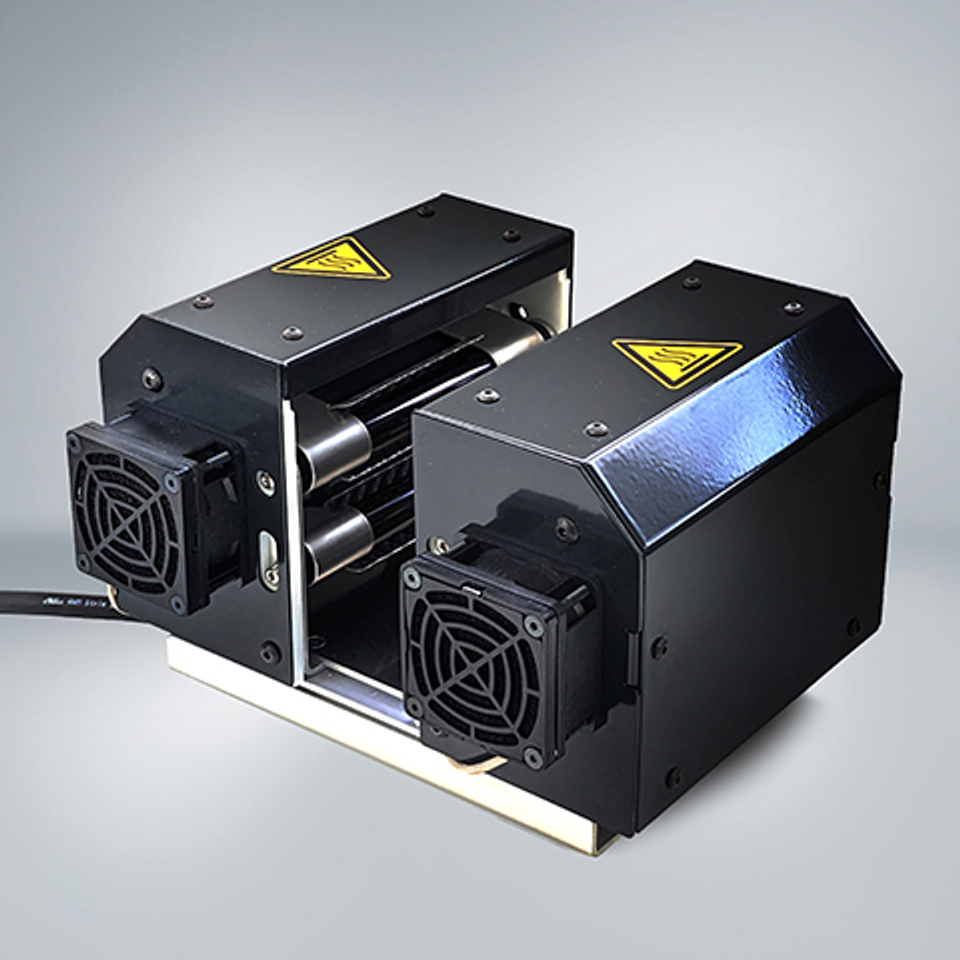

Heat ShrinkingIRES 60mm

The infrared shrinking appliance IRES is a stationary tool for processing large product diameters that require a wider shrinking zone – available in two different sizes.

Heat ShrinkingIRES 120mm

The infrared shrinking appliance IRES is a stationary tool for processing large product diameters that require a wider shrinking zone – available in two different sizes.

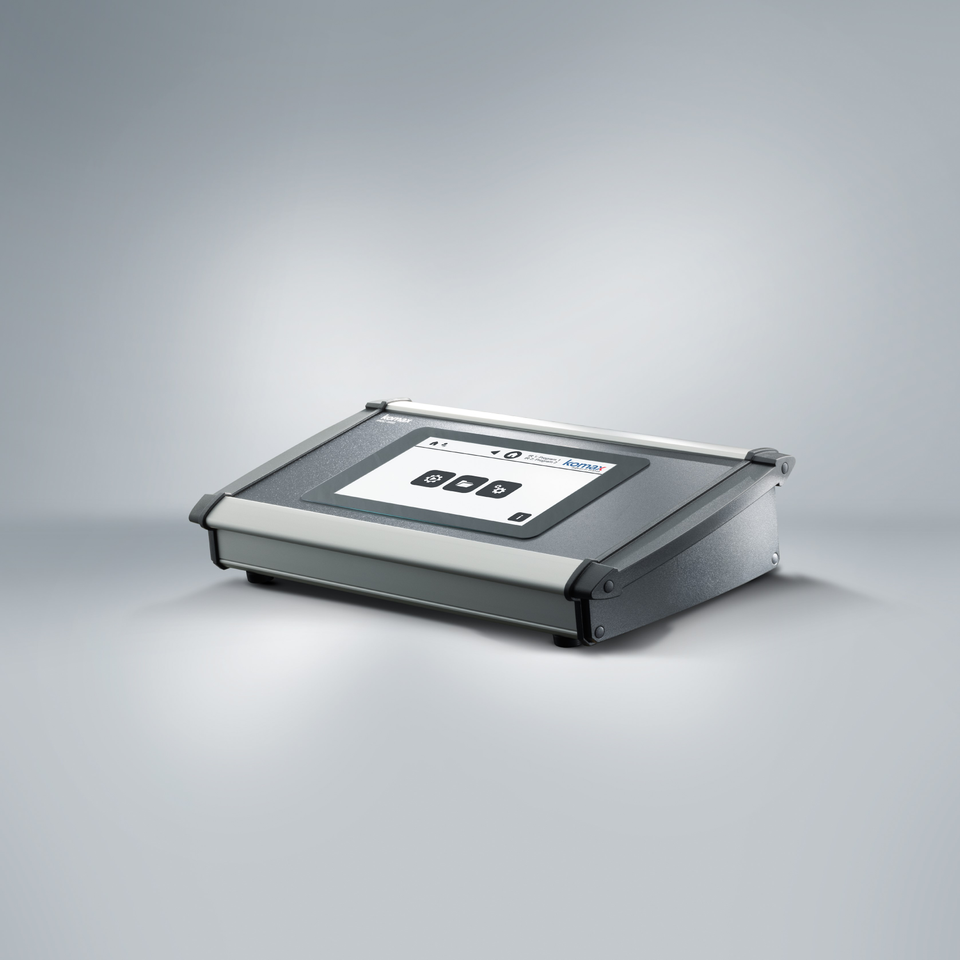

Heat ShrinkingIRDC-2000-1

The IRDC-2000 is a digital control unit designed to manage the heating process of infrared shrinking appliances – optional with two channels to control two different appliances.

Heat ShrinkingIRDC-2000-2

The IRDC-2000 is a digital control unit designed to manage the heating process of infrared shrinking appliances – optional with two channels to control two different appliances.

Heat ShrinkingSTCS-evo500TS

The Heat Shrinking Tube System STCS-evo500TS is designed for workbench applications. With optional tools, it can work on end splices, ring terminals and other special applications.

Heat ShrinkingSTCS-RCM

The Shrinking Tube Control System STCS-RCM is equipped with a built-in automatic centering system, which prevents mispositioned tubes by centering the shrink tube on the splice.

Heat ShrinkingSTCS-RCMM

The Shrinking Tube Control System STCS-RCMM compensates the movement of heat shrink tubes while processing with an automatic centering system – available with a 50mm or 75mm oven.

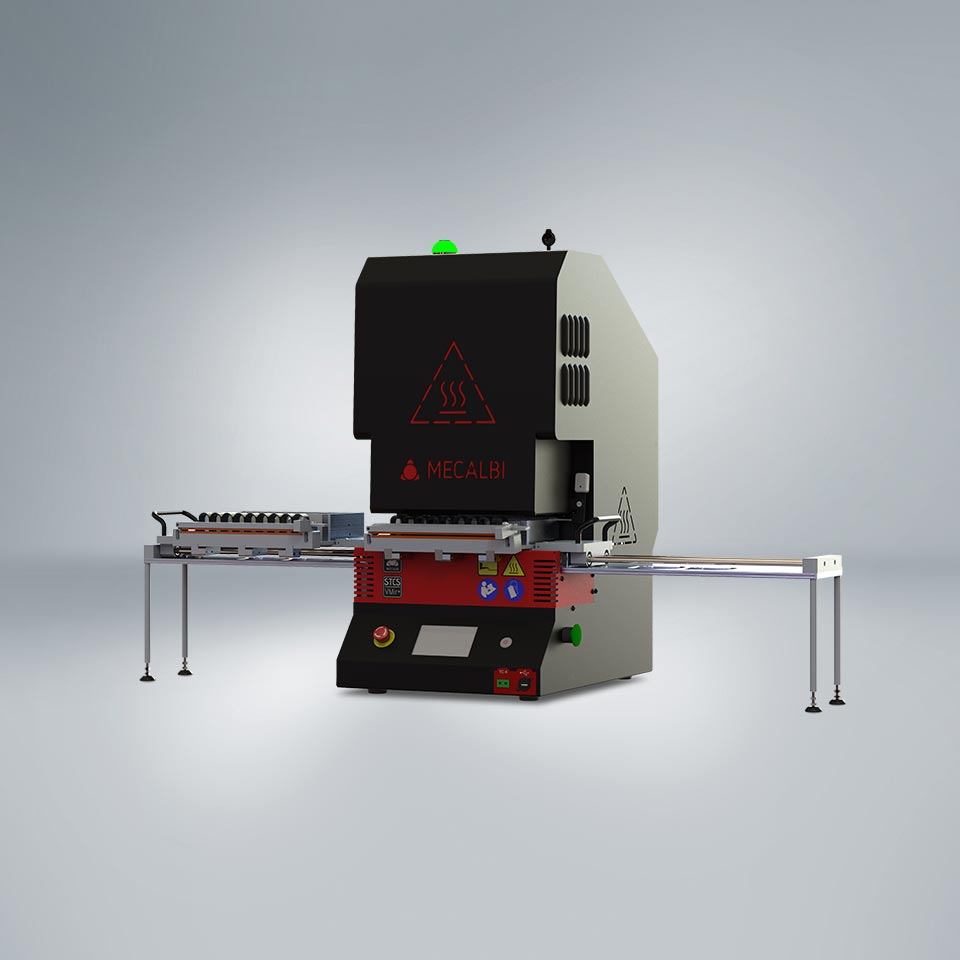

Heat ShrinkingSTCS-Vmir

The Heat Shrinking System STCS-VMir is equipped with a fast exchangeable shrinking chamber system. The fixtures are custom designed, making them ideal for special applications.

Heat ShrinkingSTCS-VMir+

The STCS-VMir+ is a variation of the standard VMir with a bigger shrinking oven and the same fast-exchangeable shrinking chamber system – making it ideal for special applications.

Heat ShrinkingSTCS-Vmir+ UV

The STCS-VMir+ UV with a built-in vision system oversees the entire process, conducting automatic quality checks on component positions, contaminated terminals, and glue overflow.

Heat ShrinkingSTCS-LC

The workbench applications STCS-LC is a versatile longitudinal conveyor based on infrared resistors, able to process several and different types of harness at the same time.

Heat ShrinkingSTCS-LC XL

The STCS-LC XL is a variant of the STCS-LC with a bigger shrinking chamber. It processes a range of harness dimensions and ensures position requirements when using custom fixtures.

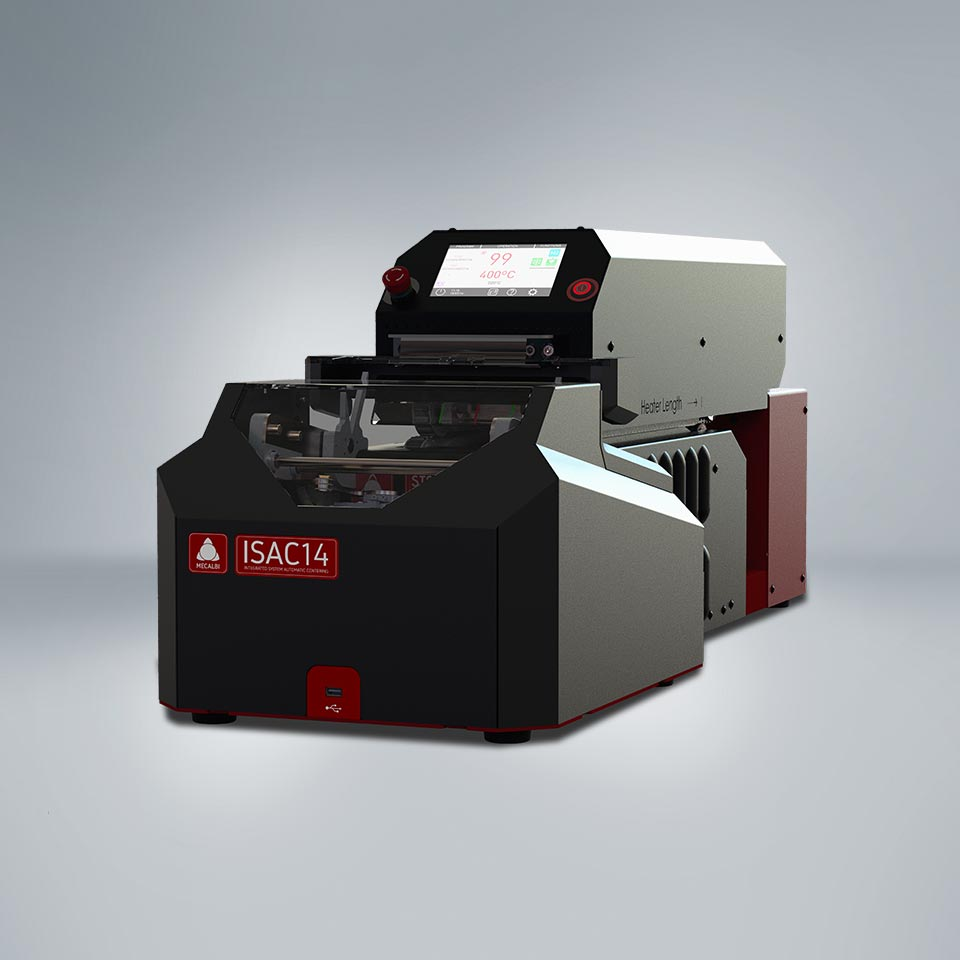

Heat ShrinkingSTCS-CS14

The STCS-CS14 is a short conveyor for large production requirements with optional Integrated System Automatic Centering (ISAC14) for heat shrink tube position and length assurance.

Heat ShrinkingISAC14

The ISAC14 Automatic Centering System is designed for integration into the STCS-CS14. The heat shrink tube length control ensures precise tube length for accurate applications.

Heat ShrinkingSTCS-CS19

The STCS-CS19 Shrink Tube Control System processes multiple parts simultaneously, offering automatic adjustment of all parameters to pre-programmed values, like conveyor speed.

Heat ShrinkingSTCS-CS19TS

The STCS-CS19TS with a large heat shrink conveyor offers an optional Automatic Centering Device (ISAC19) and offset definition, ensuring the efficient processing of linear splices.

Heat ShrinkingISAC19

Suited for the STCS-CS19TS, the ISAC19 Automatic Centering System uses an adjustable electrode for splice detection to control heat shrink tube dimension and accurate positioning.

Heat ShrinkingSTCS-CST

The compact conveyer STCS-CST processes end splices, connectors, and terminal applications in a fast and continuous manner. It is also equipped with a heat shrink tube stopper.

Heat ShrinkingSTCS-RTTS DYCOD

The STCS-RTTS DYCOD system features two workstations with independent shrink parameters. It includes tooling fixtures, doors with locks, and dynamic cooling to enhance the process.

Heat ShrinkingSTCS-MYX

The STCS-MYX reduces dead-time with two independent workstations, a shuttle oven to move between stations, and optional RFID technology for accurate fixture detection.

Heat ShrinkingSTCS-PHDir

Designed for line panel applications, the STCS-PHDir Shrink Tube Control System comes with parameter definition and a portable unit with an infrared oven for the shrinking process.

Heat ShrinkingSTCS-B

The STCS-B Shrink Tube Control System utilizes hot air for the shrinking process. It is equipped with a control module for parameter definition processing one part at a time.