Maximum Productivity with the Innovative Transfer System

Freely movable workpiece carriers minimize the amount of production space required and the cycle times, since the modules can be arranged in a row without unnecessary free space.

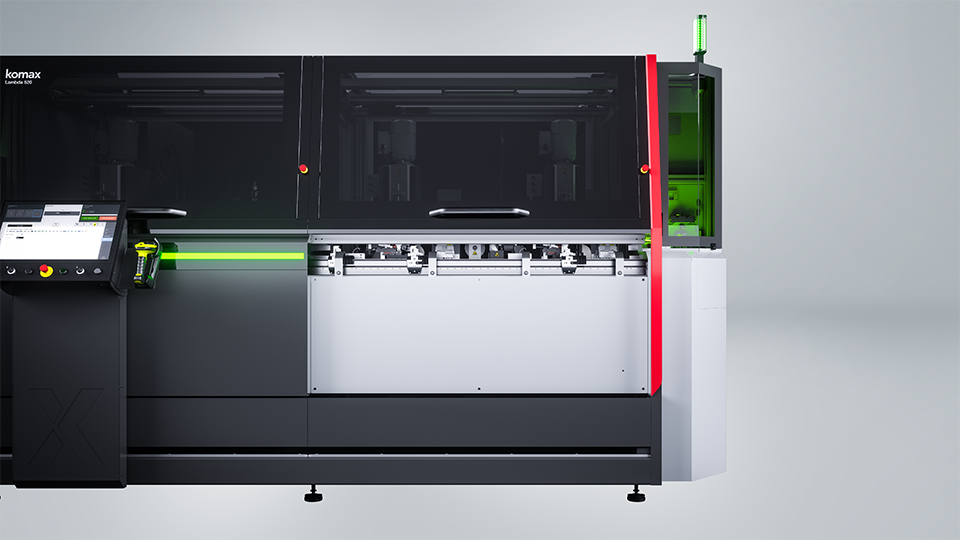

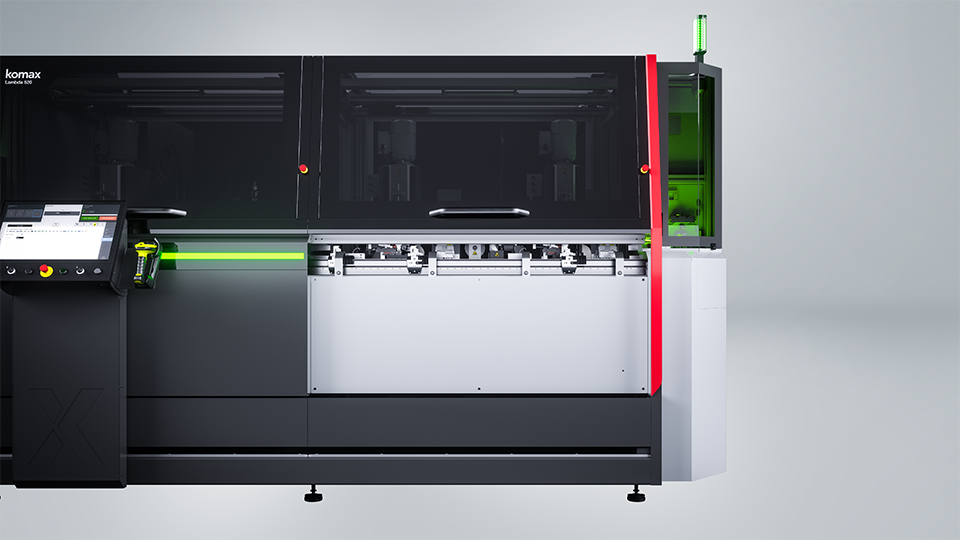

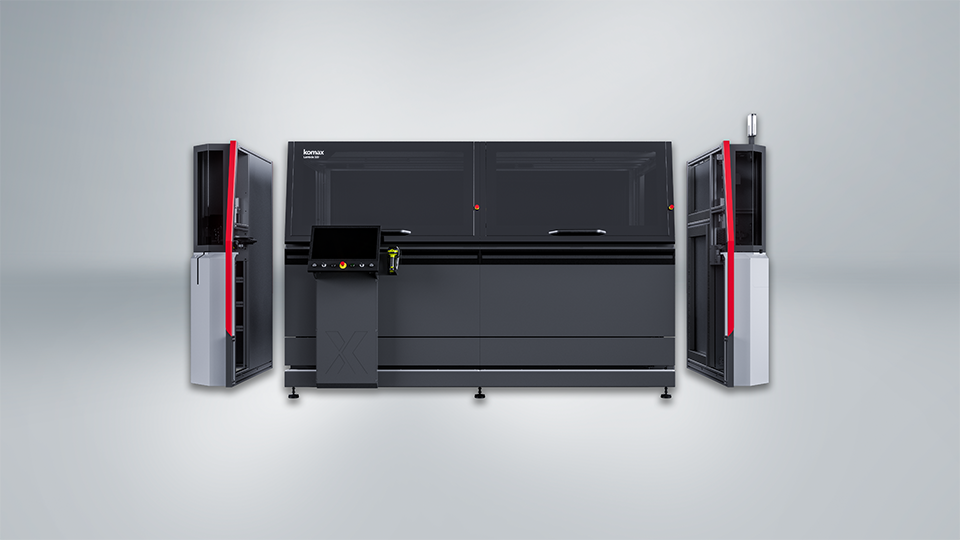

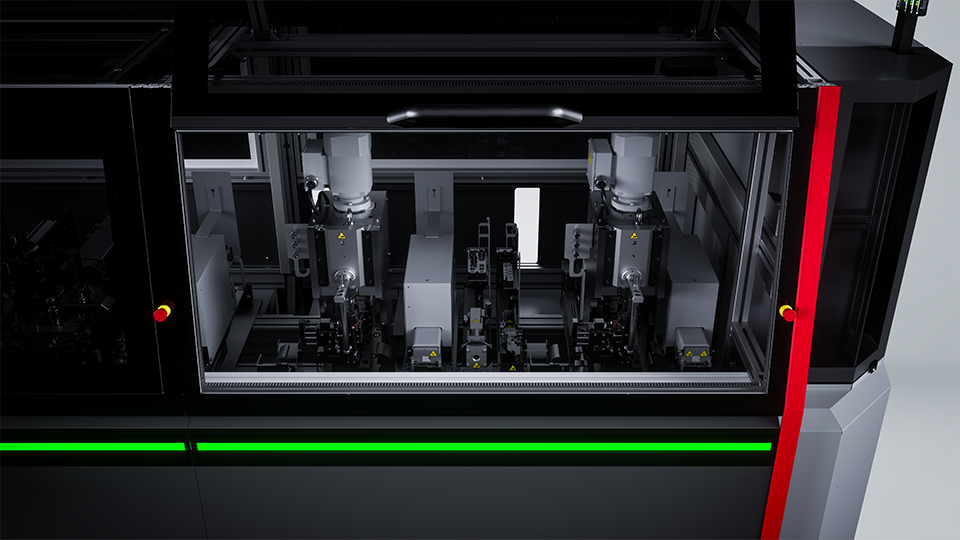

The Lambda 5 platform is a modular machine base for the fully automatic assembly of multi-step contact systems.

Freely movable workpiece carriers minimize the amount of production space required and the cycle times, since the modules can be arranged in a row without unnecessary free space.

A built-in storage solution for tooling sets and applicators, as well as simple and configurable jobs, enable the system to be converted quickly.

The Lambda 5 can be quickly and easily converted by replacing a module or upgraded to a highly automated Lambda X by converting it.

Short cycle times enable outstanding and repeatable assembly quality with low production costs per cable.

| Specification name | Specification value |

|---|---|

| Approximate energy consumption with 3'500'000 wires | 18'000 kWh |

| Cable length (uncoiled) | 1300 mm |

| Wire length coiled max. | 15000 mm |

| Wire outer diameter max. | 6 mm |

| Shortest wire length for one-sided processing | 130 mm |

| Electrical connection | 3 × 400 V AC ± 10%, 50/60 Hz |