Feeder for twisted wire

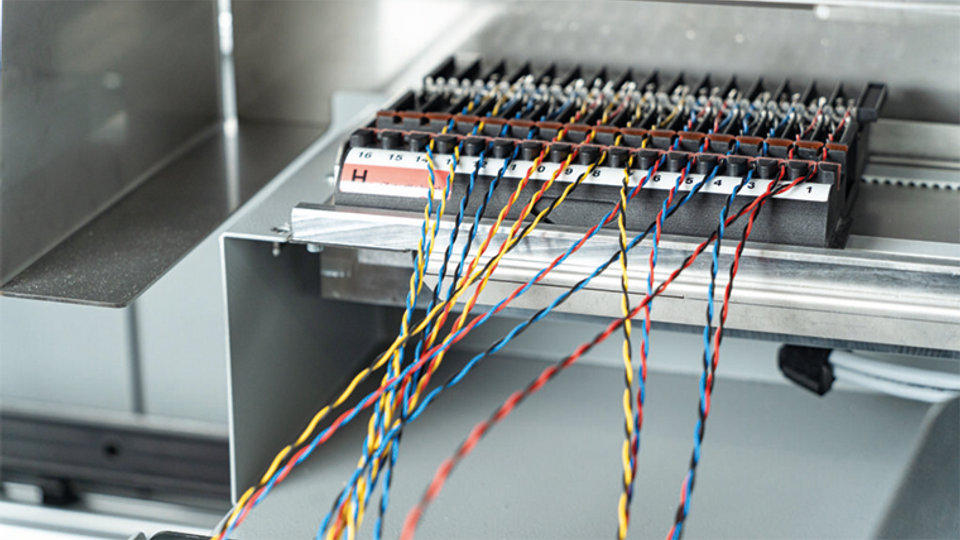

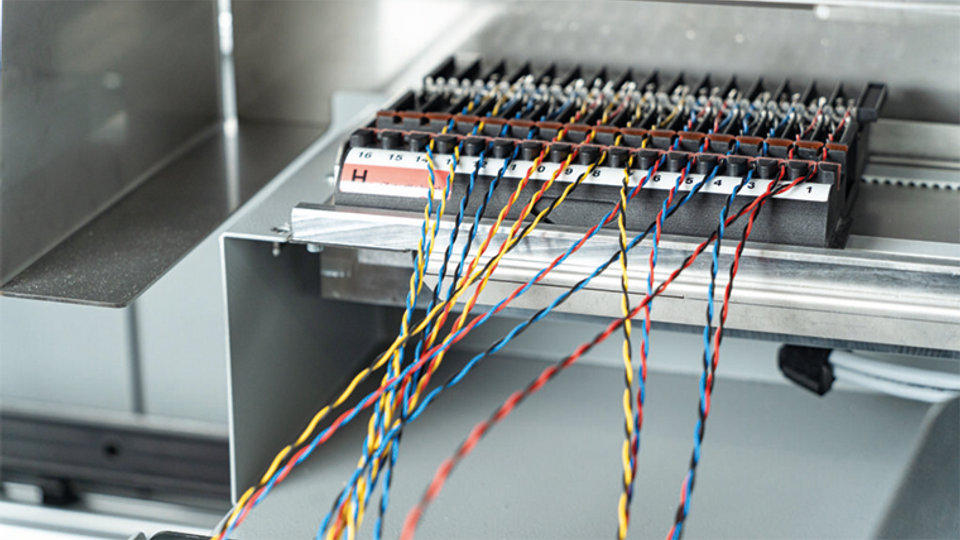

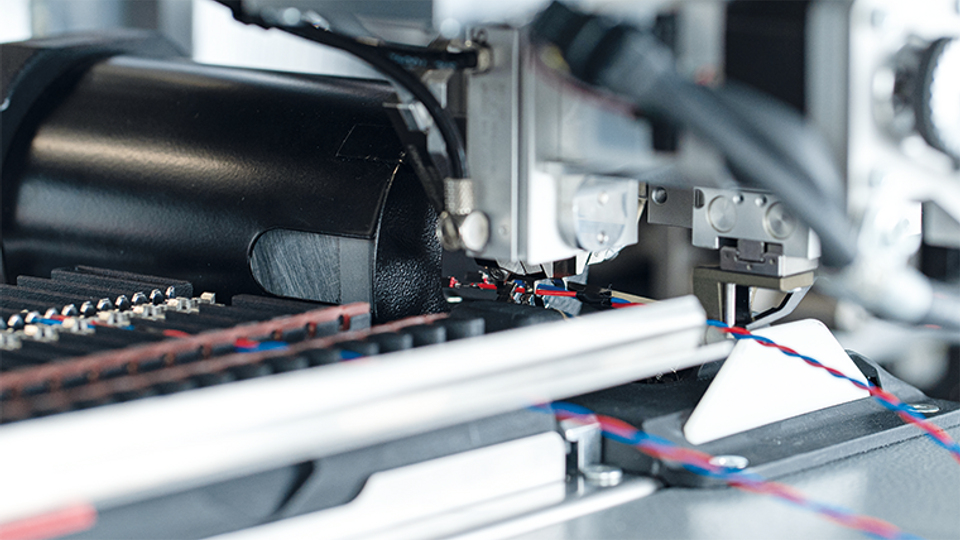

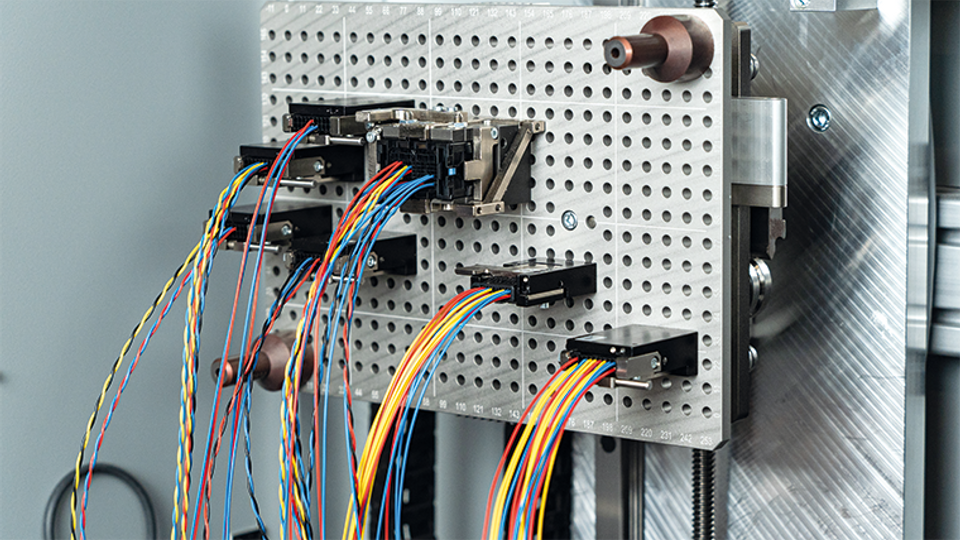

The twisted wires produced on a Sigma, for example, are fed by means of a cassette and automatically removed by the double rotary gripper.

The Omega 840 / 850 wire assembly machine automatically produces wire harnesses with individual wires with cross-sections of 0.13 –2.5 mm² as well as twisted wires.

The twisted wires produced on a Sigma, for example, are fed by means of a cassette and automatically removed by the double rotary gripper.

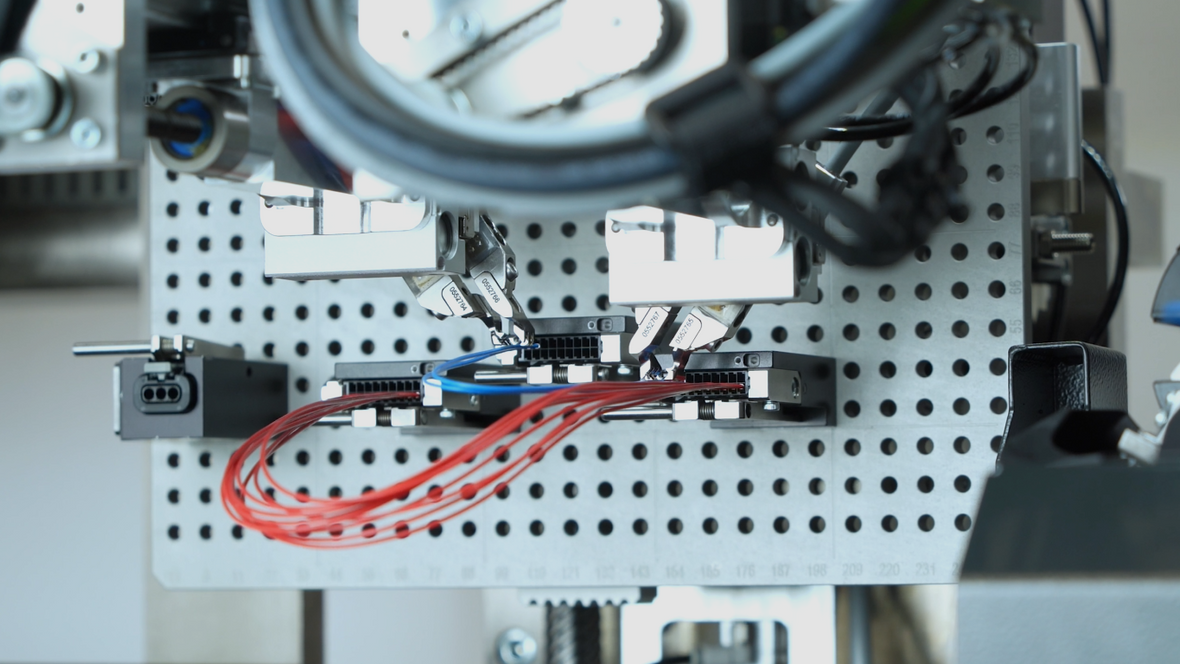

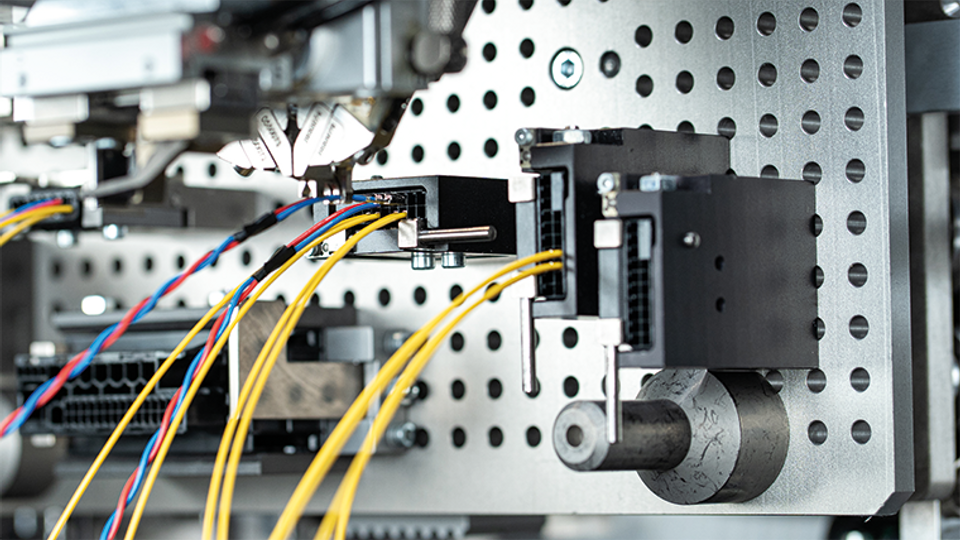

Two insertion heads insert the twisted wires into the housing correctly, fully automatically, precisely and without user intervention.

Twisted wires are measured with the TMPS optical measuring system and the angle is aligned to ensure fully automatic, correct insertion.

The Omega 8xx series produces pallets of fully assembled single and twisted wire harnesses fully automatically and extremely efficiently.

| Specification name | Specification value |

|---|---|

| Wire cross section (twisted pair) min. | 0.13 mm² |

| Wire outer diameter (twisted pair) max. | 1.6 mm |

| Cycle time per loading (twisted pair) | 2.2 – 4.4 sec |

| Wire cross section (twisted pair) max. | 0.75 mm² |

| Shortest wire length for one-sided processing | 240 mm |

| Shortest wire length for two-sided processing | 300 mm |