Central vehicle electrical systems too complex for further expansion

Automotive Ethernet and zonal data gateways enable automated production

As a trailblazer for autonomous driving, smart driver assistants require fast, redundant data transmission. Their slim E/E architecture reduces vehicle weight and paves the way for fully automated wire harness production.

Zonal gateways simplify E/E architecture

Today, numerous networked function controls send their data via long cable runs to the vehicle’s central on-board computer. Complex E/E architectures have been created as a result of the wide range of functions that has been growing for years, and these architectures can only be expanded with great effort and expense. In addition, many long cables unnecessarily increase the vehicle weight and take up valuable installation space.

Automotive Ethernet connector systems and data cables, on the other hand, transfer even larger quantities of data at high speeds in the multi-gigabit range. New concepts for a simpler communication infrastructure envisage zonal gateways for processing in real time, which is an essential prerequisite for the next level of autonomous driving.

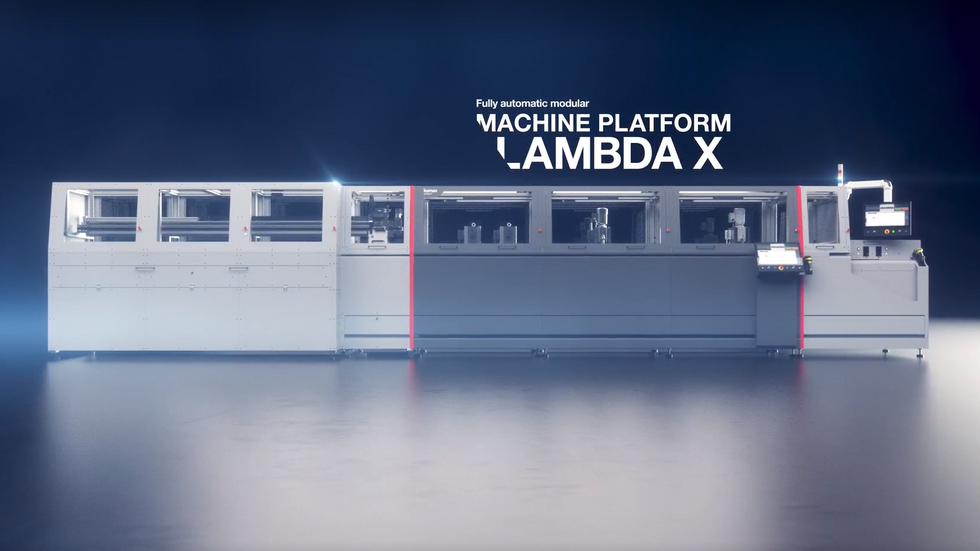

Automated manufacturing of automotive Ethernet-based E/E systems

Compared to the currently customized, complex cable harnesses, the smaller, simply structured wire harnesses for zonal vehicle electric systems are ideal for automated production. Automated production significantly increases productivity while maintaining consistently high quality.

The automated processes are designed both for increasing production volumes and for the new requirements for wire harness assembly.

These include:

- Lower tolerances to interferences

- Higher precision in conductor processing and connector assembly

- Miniaturization: Smaller conductor cross-section and shorter strip length for smaller connectors and lower weight

- New transfer technologies between the process modules reduce the machine footprint by up to 45 % and enable maximally flexible Ethernet assembly.