Safe. Effective. Transparent.

Smart Quality Assurance for Cable Assemblies for Autonomous Vehicles

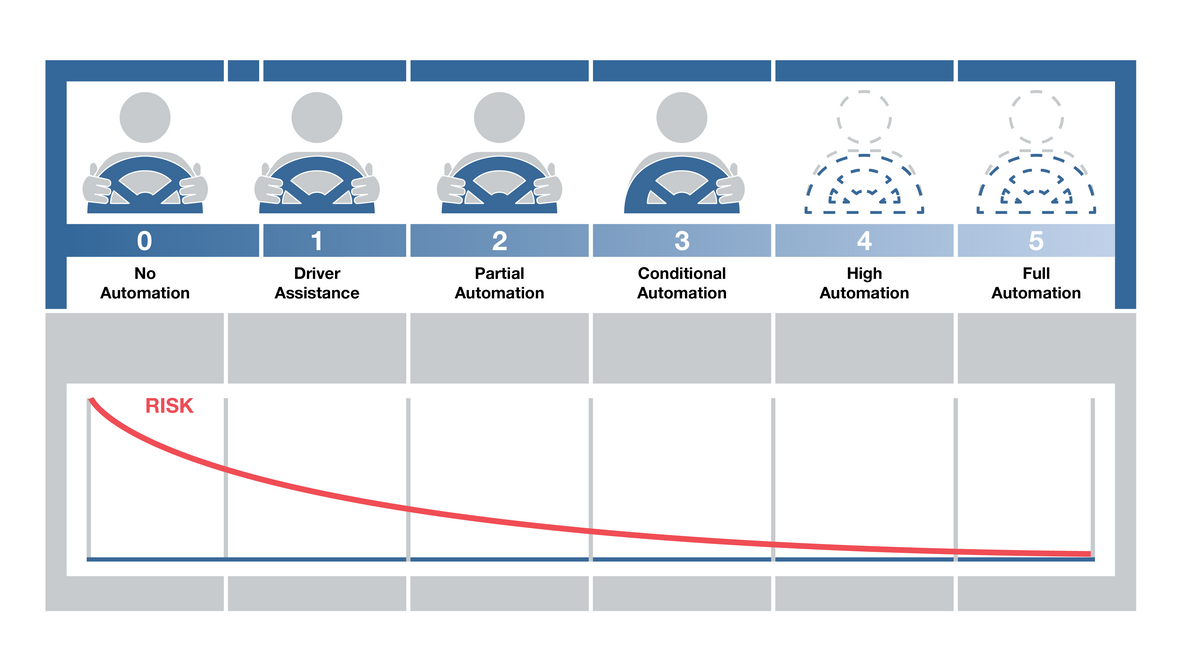

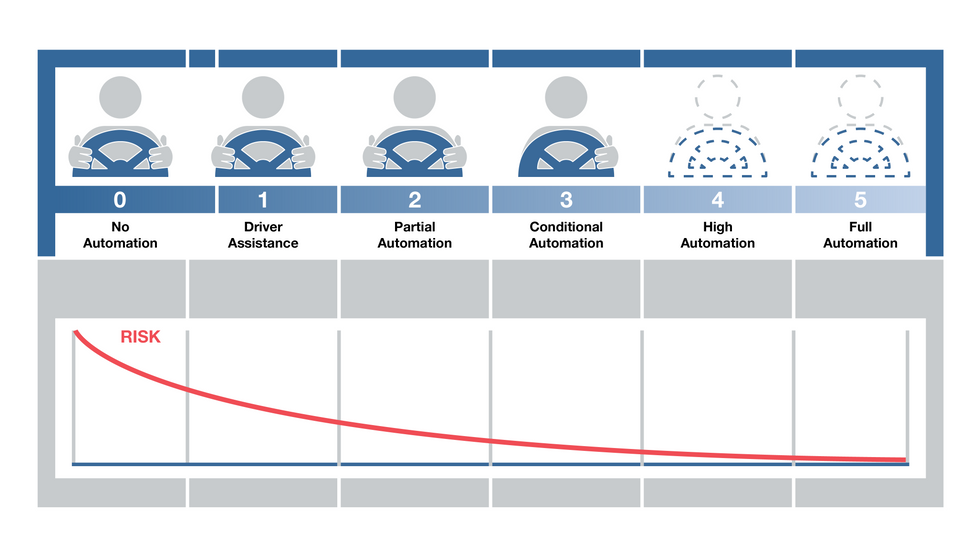

Autonomous driving requires controllable, traceable quality. The more automated the driving, the higher the requirement. As the level of automation rises, it is essential to minimize the risks that significantly influence quality.

Reduce error rate through automated quality assurance

Brief inattentiveness or poor lighting conditions can cause workers to easily overlook even the slightest mistakes in the visual inspection of the wire harnesses produced. Even with the dual-control principle by very well-trained operators. As a result, the quality-relevant risk factors must be minimized or excluded.

The solution: Reliable and operator-independent quality inspection ensures error detection. An automated process is also significantly more efficient, and the consistently high quality is reproducible and fully traceable.

Success factors of automated monitoring

In order to successfully automate quality assurance, quality characteristics must be clearly defined and automatically monitored during the manufacturing process. Any external influences on quality monitoring must be avoided. The biggest factor to avoid is human interaction.

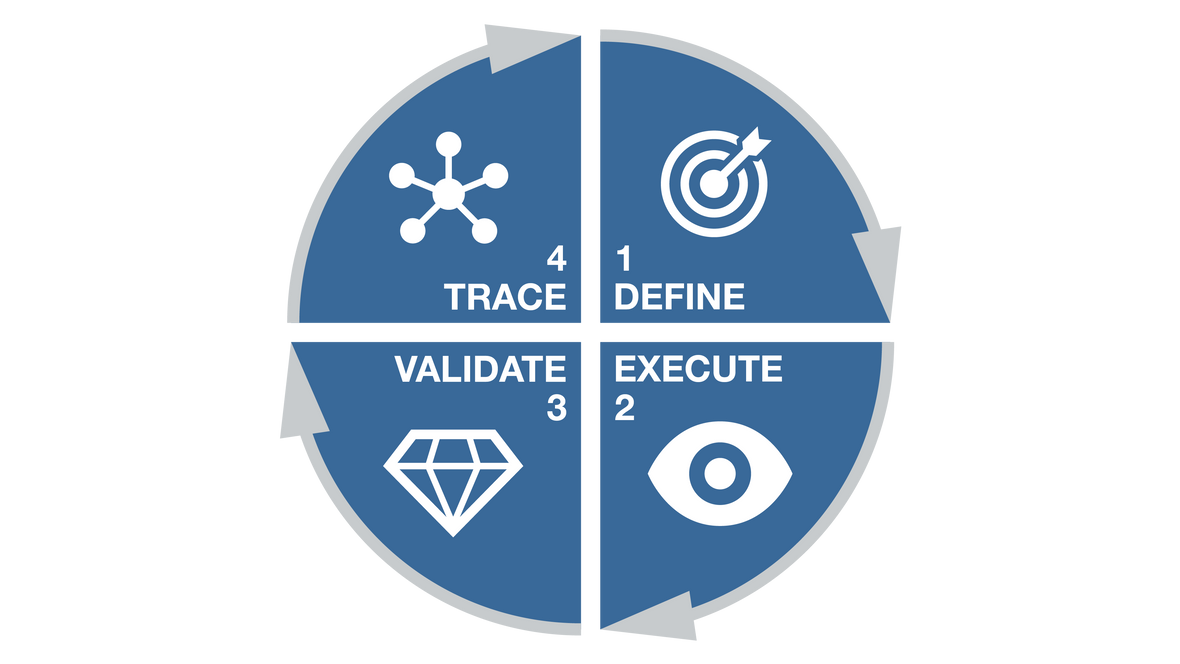

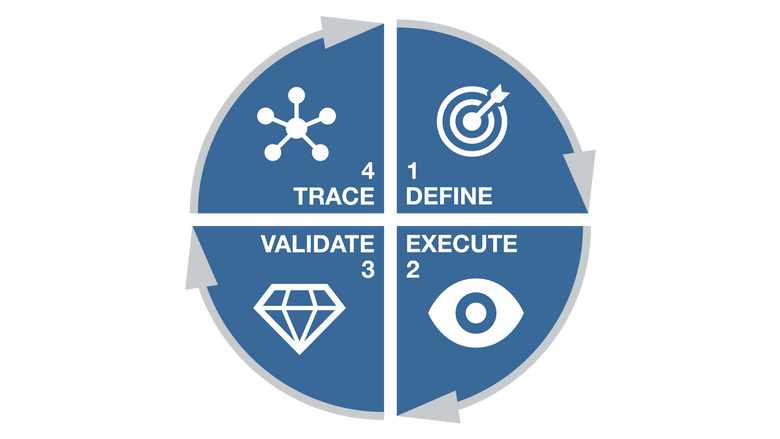

Phases of smart quality assurance:

1. Define

First, quantifiable parameters must be defined with their limit values for deviations.

2. Execute

The real measured values are determined fully automatically without operator influence and can be reproduced.

3. Validate

The comparison of the measured values with the defined parameters is also automatic. In this way, the process ensures that no faulty wire harnesses are installed.

4. Trace

Due to the fact that quality assurance has been clearly defined and fully automated, it can be reconstructed at any time. As proof, it is sufficient to know the limits of the specification parameter and the version of the evaluation procedure.

Simplified quality assurance with high value added

The zero-error strategy in wire processing quickly pays off:

- Clear, easily communicated target definition

- Controllable process

- No expenditure for operator training required

- Less data required

- Fast processing of quality cases and recalls

Conclusion: In order to minimize risks to life and limb, for example, during autonomous driving, more reliable products are needed. They require a reliable and controllable production process. Komax pursues this goal with its extensive portfolio of quality tools.