Scalable, excellent and economical

Pioneering achievement in automated assembly of high-voltage cables

Individually scalable, from semi-automated to highly automated production platforms – this is the future of HV cable assembly. Configurable modules with integrated quality checks and always at the forefront of the latest technologies.

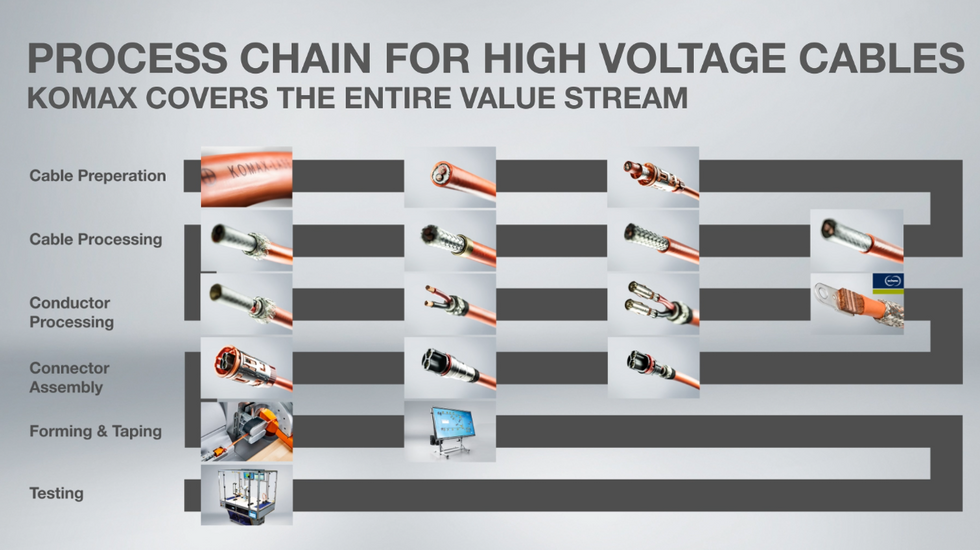

Scalable automation of end-to-end assembly of high-voltage wire harnesses

Improper functioning of the power supply in electric vehicles can result in vehicle failure or hazardous situations. Connector assembly therefore means compliance with narrow tolerance fields as well as technically clean processes with cycle times within seconds. Automated, safe solutions minimize the problems of manual production. The combination of an individual production concept and a modular, dynamically configurable production platform provides a step-by-step introduction to automated wire assembly.

Which sub-processes have the highest priority depends on a solution concept developed together with Komax. One thing is certain: The more the processes are interlinked, the better the productivity and quality. The machine layout is tailored precisely to individual requirements while taking economic aspects into account.

Production clusters optimize machine utilization

The assembly process for the high-volume production of diverse types of high-voltage connectors has many individual steps. While semi-automated production focuses on critical processes, a higher degree of automation allows multiple process steps to be combined. At economically justifiable expense, this clustering offers further optimization potential, for example in logistics. Here, the automated transport of wires from machine to machine increases productivity – without the use of fully automatic machines.

HV connector design defines degree of automation

The extent to which the automation of sub-processes in the assembly of high-voltage cables makes sense must be evaluated on a project-specific basis. The automation concepts developed correspond to the components to be processed and the production volume. However, factors such as quality assurance and wire material also play an important role:

- What should be checked and measured and what are the underlying parameters?

- Which stripping technology is suitable? Is laser, other standard processes or the hybrid rotary process called for?

The great advantages of automated production lie in the high productivity and very high level of quality. Quality assurance systems integrated into manufacturing processes offer opportunities to minimize material waste, and their digital production logs provide traceability.