SMART FACTORY by KOMAX

A networked factory produces more profitably while maintaining top quality

The process data from networked machines yields all information for more efficient production. It forms the basis for high machine availability, preventive, predictable maintenance, better energy management and optimal quality parameters.

Man and machine working hand-in-hand

The Industrial Internet of Things (IIoT) is currently at the heart of the SMART FACTORY by KOMAX. As a central monitoring tool hosted in Switzerland, it records the data of the net-worked machines, processes them in real time and visualizes them graphically on a dashboard. It provides a transparent overview of how high the utilization of the machines is, how well they perform, what quality they deliver and how the energy management is arranged. Adapted production planning with corresponding processes enables you to make up for cost-intensive peaks in energy consumption.

At the same time, machine utilization can be optimally managed through targeted planning and control of production orders. Process data also yields information on efficient changeover times and the best time for the next maintenance.

The IIoT is the ultimate analysis tool for making fact-based decisions, leveraging optimization potential and minimizing risks.

Monitoring of this kind offers many other advantages, such as:

- Real-time visualized production output that can be used to make comparisons and predictions.

- Reports available at the touch of a button.

- Quality management based on centrally managed production parameters. Centrally controlled machines ensure consistently high quality.

- 100 % traceable production and quality.

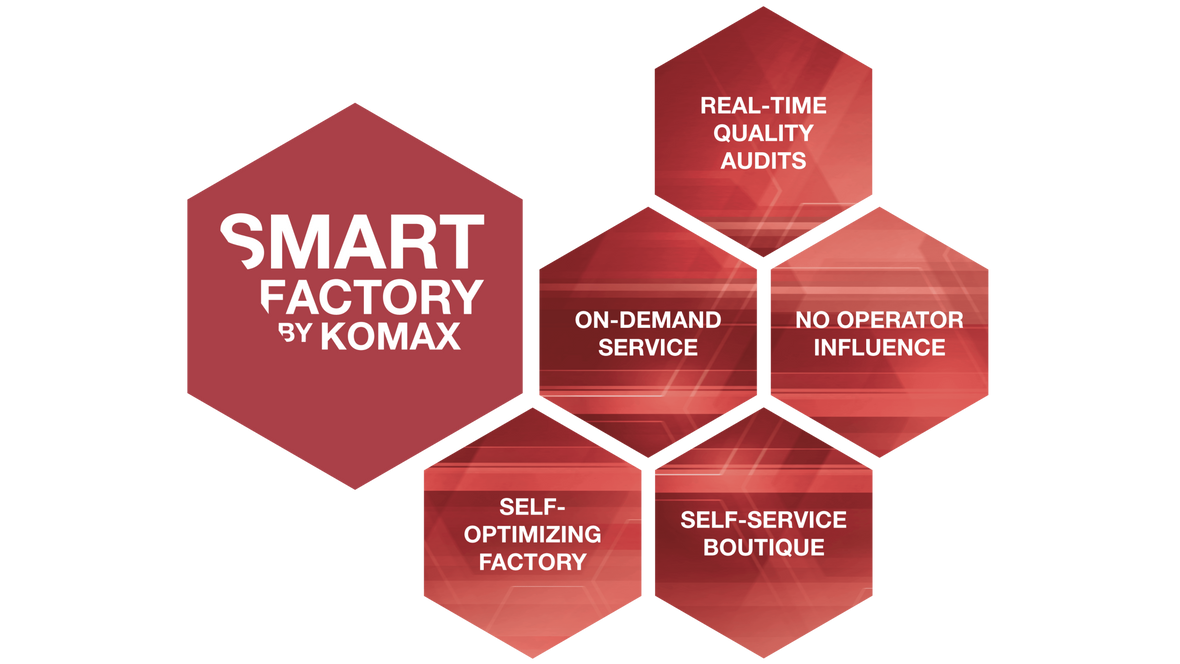

Vision of the SMART FACTORY by KOMAX

Automated, data-driven cable assembly means solving

complex production processes more efficiently and economically without

compromising on quality. Among the biggest challenges at the moment are:

- Progressive miniaturization of contact systems

- Global shortage of skilled workers and rising personnel costs

- Lean, flexible and scalable production concepts without time-consuming material changes and setup times

- Continuously automated production of customer-specific cable harnesses

- Higher quality requirements and end-to-end traceability

Komax has a vision for the SMART FACTORY by KOMAX. It strives for the implementation of the following five components that provide solutions for major challenges:

No Operator Influence

SMART FACTORY by KOMAX minimizes operator influence. To achieve this, Komax is developing fully automated and networked solutions. How you benefit: You reduce labor costs and your reliance on your workforce. Productivity and transparency improve while quality remains consistently high.

Self-optimizing Factory

The self-optimizing factory improves productivity while also reducing quality costs. To achieve this, Komax provides cloud-based algorithms based on production and behavioral data. How you benefit: You significantly improve machine utilization and reduce your quality costs.

Self-service Boutique

Komax offers access to a digital self-service boutique. Customers benefit from services such as product and spare parts ordering, web-based training, software downloads and upgrades, license management plus analysis and optimization tools. How you benefit: You can access Komax services anytime, anywhere, and get a customized picture of your business.

On-demand Service

Komax offers solutions and services on demand. These include performance or usage-based payment for systems, financing and leasing services, or procurement of production capacities, for example, to handle production peaks. How you benefit: You reduce your capital requirements and increase your flexibility, stability, and responsiveness.

Real-time Quality Audits

SMART FACTORY by KOMAX enables real-time quality audits. Quality data is collected using IoT technology, stored in the cloud and processed in a user-friendly manner. This makes it easy for customers to generate quality reports immediately. How you benefit: You can demonstrate compliance with quality requirements at any time and trace processes.

Innovation continues: self-regulating systems

As an innovation driver and market leader in automated wire processing, we are continuing to invest in the further development of intelligent, reliable and cost-optimizing solutions. The vision of the SMART FACTORY by KOMAX is continuously being implemented.

Future systems will adjust themselves and thus regulate the production process inde-pendently – even cross-plant. Together with our customers, we continue to work to make life easier, more convenient and safer.

Find out here which future-proof solutions are already available today or are in development.